Oil analysis: Everything You Need to Know

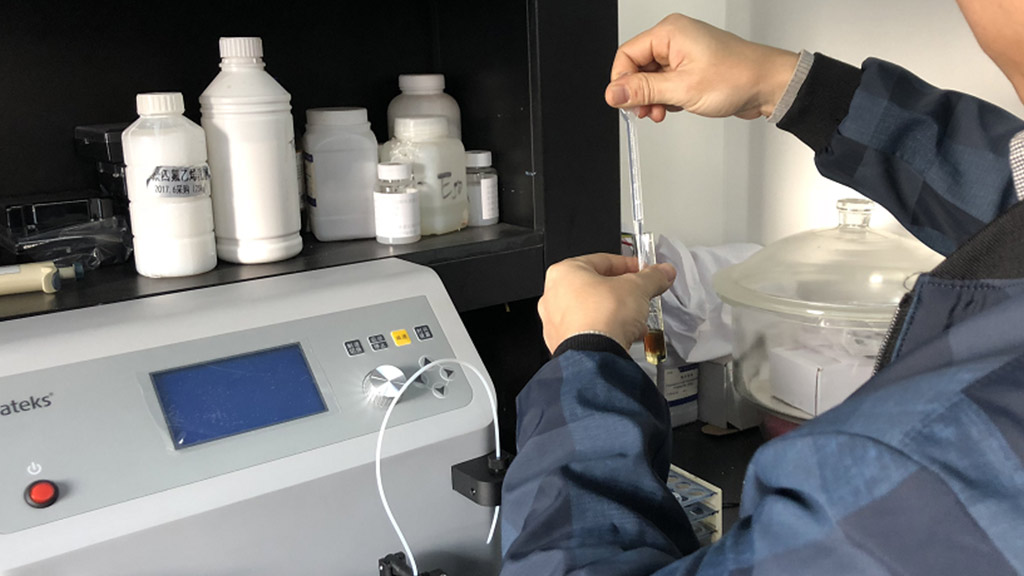

Oil testing and Oil analysis, is a crucial process used to evaluate the condition and quality of various types of oils, including lubricating oils, hydraulic oils, transformer oils, and others. This analysis helps ensure the efficient operation of machinery and equipment, prevent costly breakdowns, and extend the lifespan of the oil and the equipment it serves. Here are the key aspects of oil testing and analysis.

Chemical Composition Analysis: This involves examining the chemical makeup of the oil, including its additives and contaminants. It helps identify any changes in the oil's composition that might indicate degradation or contamination.

Physical Properties Testing: This includes assessing various physical characteristics of the oil, such as viscosity, density, colour, and acidity. Changes in these properties can indicate issues with the oil's quality or suitability for its intended purpose.

Wear Debris Analysis: In machinery and engines, wear debris from moving parts can be suspended in the oil. Analyzing this debris can provide insights into the health of the equipment and help detect abnormal wear patterns or impending failures.

Contaminant Analysis: Oil can become contaminated with foreign substances like water, dirt, or other fluids. Detecting and quantifying these contaminants by employing efficient oil testing methods is essential for maintaining the oil's performance and protecting the longevity of the equipment.

Spectroscopy: Spectroscopic techniques, such as Infrared (IR) Spectroscopy, can identify the presence of specific compounds or contaminants in the oil. This helps detecting additive depletion and identifying contaminants.

Particle Counting: Particle counters are used to measure the number and size distribution of particles in the oil. An increase in particle count can signal abnormal wear or contamination.

Oil Condition Monitoring: By regularly monitoring oil samples taken from machinery or systems, analysts can establish baseline data and track changes over time. This allows for the early detection of issues before they lead to equipment failure.

Dissolved Gas Analysis (DGA): In the case of transformer oils, DGA is crucial. It involves analyzing the gases dissolved in the oil to detect potential faults or overheating in electrical transformers.

Tribology Analysis: Tribology is the study of friction, wear, and lubrication. Oil analysis in terms of tribology can include assessments of friction and wear characteristics to optimize lubrication in machinery.

Interpretation and Recommendations: After conducting the oil analysis, experts interpret the results and make recommendations. These recommendations can include changing the oil, adjusting maintenance schedules, or taking specific actions to address identified issues.

Critical Insights: The Importance of Oil Analysis and Testing

Equipment Health Monitoring: Oil analysis helps monitor the health of machinery and equipment by detecting early signs of wear, contamination, or abnormal operating conditions. This proactive approach prevents unexpected breakdowns and reduces costly downtime.This extends the lifespan of the machinery and reduces the need for costly replacements.

Cost Savings: Preventive maintenance based on oil analysis is more cost-effective than reactive repairs. Addressing problems early on helps avoid expensive repairs and replacements, ultimately saving money for businesses.

Optimized Lubrication: Oil analysis ensures that lubricating oils are performing at their best. It helps maintain proper viscosity and ensures that additives remain effective, which, in turn, reduces friction, heat, and wear in machinery.

Environmental Impact: Effective oil management through oil analysis reduces oil waste and minimizes the environmental impact of disposing of used oil improperly. This aligns with sustainability and environmental responsibility goals.

Safety: In certain applications, such as in the electrical industry (transformer oil analysis), monitoring oil conditions is crucial for safety. Detecting abnormal gases or contaminants in transformer oils can prevent catastrophic failures and hazards.

Quality Assurance: For industries like food production and pharmaceuticals, where oils are used in processing and packaging, oil analysis and oil testing help ensure product quality and compliance with regulatory standards.

Energy Efficiency: Well-maintained machinery operates more efficiently, leading to energy savings. Monitoring oil conditions can contribute to energy conservation efforts.

Data-Driven Decision Making: Oil analysis provides valuable data that can inform maintenance schedules, equipment replacement decisions, and overall operational strategies. It helps organizations make informed choices based on empirical evidence.

Predictive Maintenance: Oil analysis when integrated with other predictive maintenance techniques, helps create a comprehensive maintenance strategy. Predictive maintenance minimizes downtime, maximizes equipment availability, and reduces operational disruptions.

Empowering Industries: The Vital Role of Oil Analysis Methods

Analytical Ferrography in Tribology:

- Diagnoses machinery health by analyzing all metal based wear particles and non-metal based wear particles in lubricants. Also analyses if the wear is caused by sliding wear, cutting wear, rubbing wear, scuffing wear, fatigue wear, etc.

- Key components: Magnetic field and ferrograms.

- Applications: Predictive maintenance, root cause analysis, quality control.

Ferrous Wear Concentration:

- Measures iron-based wear particles in fluids.

- Key for wear detection, maintenance planning, and component health assessment.

Elemental Spectroscopy for Composition Analysis:

- Identifies elemental composition.

- Techniques include AAS, ICP, XRF, RDE and EDS.

- Applications: Environmental monitoring, metallurgy, pharmaceuticals, forensics, and geological exploration.

PQ Index (Particle Quantifier Index):

The PQ Index assesses the total Iron (Ferrous) metal content by applying a magnetic field to the oil regardless of size or shape of the debris. PQ Index gives the index of concentration of iron particles however big or small in shape and size which contribute to the wear in the oil.

RDE Electrode (Rotating Disc Electrode):

In-service oil testing is conducted by Rotating Disk Electrode (RDE) by using Optical Emission Spectroscopy (OES) to measure the amount and level of Wear Metals, Contaminant Metals, Multi-Source Metals and Additive Metals.

Locating an Oil testing lab near me: Your Guide to Precision Testing

Industry Associations: If you are involved in a specific industry that requires oil analysis, check with industry associations or trade organizations related to your field. They may have a list of recommended labs.

Consult with Suppliers or Manufacturers: If you use specific types of lubricants or oils in your equipment, consider contacting the manufacturers or suppliers of these products. They often have partnerships or recommendations for local oil analysis labs.

Ask for Recommendations: Reach out to colleagues, peers, or professionals in your industry who might have experience with oil analysis. They may be able to recommend a reputable lab in your area.

Contact Local Industrial Suppliers: Industrial supply stores or companies that serve your industry often have connections with local oil analysis labs. They can provide recommendations or even offer testing services themselves.

Check Local Business Listings: Local business listings and classified ads in newspapers or online platforms may also list oil analysis labs in your area.

Atlas Lab: Your Trusted Partner for Oil Analysis Excellence

Atlas Lab stands as a premier Testing, Inspection, and Certification Company, holding accreditation from NABL and certification according to ISO 17025 standards. Comprising a team of passionate and highly skilled professionals, our expertise extends to Fuel Oils, Lubricating Oils, and Petroleum products, catering to industries of all sizes worldwide. Our advanced laboratory, backed by over four decades of combined technical experience, conducts comprehensive chemical and physical analyses in accordance with ASTM, ISO, IP, Indian Standards, British Standards, European Standards, and American Standards. Furthermore, we collaborate closely with our clients, tailoring our services to align precisely with their requirements and specifications.

Our overarching goal is to consistently set the benchmark for oil testing and analysis by fostering continuous innovation and leveraging our technical proficiency. At Atlas Lab, we prioritize customer satisfaction by delivering cutting-edge solutions that are both accurate and cost-effective, ensuring swift service delivery.